DIE CASTING LINE

-

- We operate a fully-automated system covering everything from molten metal feeding to material trimming, and also operate a real-time monitoring system for parts defects and die casting conditions. We operate a seamless die casting utility system using vacuum and Super Cool.

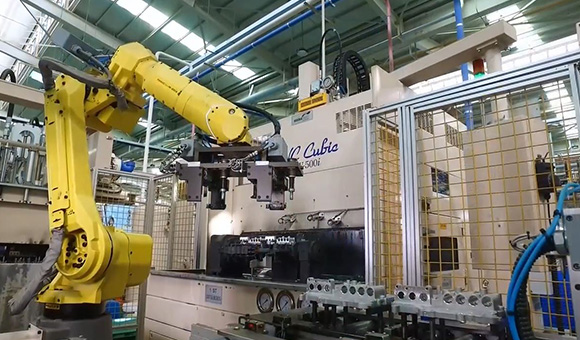

PROCESSING LINE

-

- We perform precise machining of spool assembly holes for transmission control by using our FAS unmanned automation system.

- We also perform precise machining of solenoid valve assembly holes and assembly joint surfaces.

- We apply deburring technology for clean parts (cascade, ultrasonic cleaning and x-ray system).

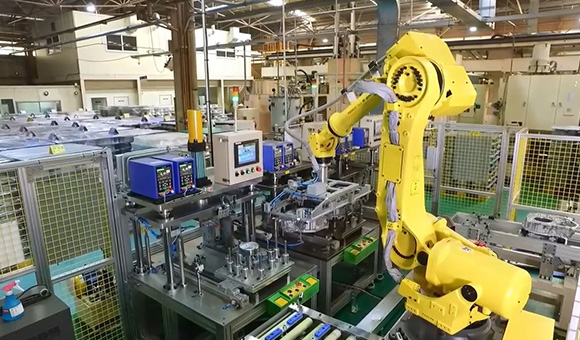

PROCESSING MEASURING LINE

-

- We apply a product identification system to prevent incorrect product mounting or application.

- The system automatically detects product models and measures depth and bore.

- We apply SPC(Statistical Process Control) to record and judge measurement data, work data and assembly data.

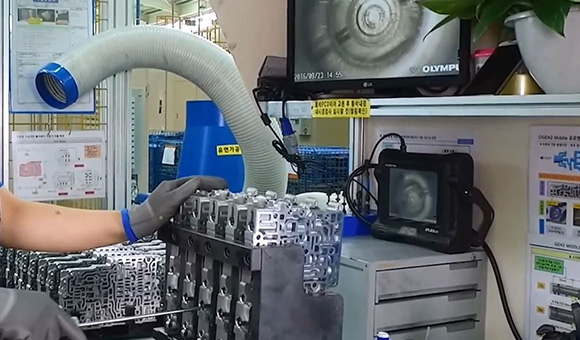

ACCEPTANCE INSPECTION LINE

-

- We machine a valve body using a high-resolution endoscope and assemble the spool to it.

- We detect defects on the processed inner surface of holes, such as scratches and blisters.

- We inspect defects on holes of hydraulic spool valves.